Dishwasher Parts Breakdown: Key Components and How to Fix Common Issues

In commercial kitchens, the dishwasher is one of the most essential pieces of equipment, handling nonstop loads during lunch rushes, dinner services, and catering operations. When even a single component starts to fail, such as a dishwasher not draining, it can slow down service, affect sanitation standards, and create costly delays for the entire restaurant. Understanding how the internal parts of a commercial dishwasher work is key to preventing breakdowns and keeping operations running smoothly.

Commercial dishwashers are engineered for heavy-duty cycles, rapid turnaround times, and strict hygiene requirements. By knowing the purpose of each major part and watching for early signs of damage, restaurant teams can troubleshoot issues quickly and extend the life of their machine. This guide explains the essential components and practical fixes every commercial kitchen should be familiar with.

Understanding the Key Components of a Commercial Dishwasher and Their Functions

Commercial dishwashers are engineered for high-volume cleaning, speed, and sanitation. Understanding the main components ensures optimal performance, reliability, and compliance with hygiene standards.

Pumps: Pumps circulate water throughout the dishwasher, delivering high-pressure cleaning and efficient drainage to remove food particles and leftover water.

Key Functions:

-

Deliver high-pressure water jets to remove tough food residues and grease.

-

Efficiently drain dirty water to maintain clean rinse cycles.

Effects of Malfunction: Weak spray, standing water, dishwasher not cleaning properly, and possible pump damage.

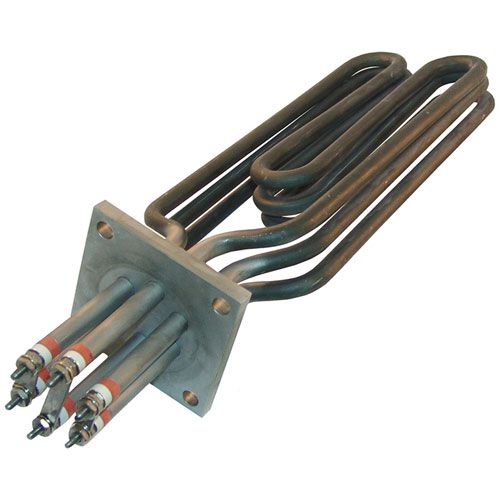

Heating Element: The dishwasher heating element raises water temperature to the levels required for deep cleaning and sanitation, ensuring dishes are hygienic and free from bacteria.

Key Functions:

-

Rapidly heat water to shorten wash cycles.

-

Maintain a high-temperature rinse for effective sanitation.

Effects of Malfunction: Longer cycles, poor drying, unsanitary dishes, and failed sanitation compliance.

Wash Arms and Nozzles: Wash arms and nozzles distribute water evenly across all dishes, ensuring full coverage and thorough cleaning even in large racks.

Key Functions:

-

Rotate to ensure complete coverage of all dishes and racks.

-

Spray water at high pressure to remove stuck-on food.

Effects of Malfunction: Uneven cleaning, water wastage, and incomplete removal of food debris.

Control Panel: The control panel serves as the operational interface, allowing staff to select wash cycles, monitor water temperature, and troubleshoot problems quickly.

Key Functions:

-

Display cycle status, temperature, and error alerts for efficient operation.

-

Enable selection of wash programs and customization for different load types.

Effects of Malfunction: Operational delays, inefficiency, and difficulty troubleshooting.

Keep your commercial dishwasher running at peak performance with PartsFe UK’s high-quality dishwasher spare parts. We offer water valves, hoses, and timers compatible with trusted brands, including Prince Castle, Stero, and Hobart.

Common Dishwasher Replacement Parts You’ll Need Over Time

Commercial dishwashers operate under heavy workloads, so knowing the most commonly worn components helps kitchens stay efficient and quickly source the right replacement dishwasher parts when needed.

Spray Arms

Spray arms are essential for distributing high-pressure water throughout the dishwasher. In commercial units, these arms experience constant stress and may develop clogs or wear.

Signs of replacement: Poor cleaning, uneven water coverage, or broken nozzles.

Heating Elements

Commercial dishwashers often use high-wattage heating elements for rapid water heating and sanitization. Over time, elements can burn out or scale up, reducing heating efficiency.

Signs of replacement: Water not reaching required temperatures, longer cycles, or incomplete drying.

Pumps and Motors

Industrial-strength pumps and motors circulate water at high pressure to handle large loads. Pumps can fail due to wear, debris, or overheating, which can affect their cleaning performance.

Signs of replacement: Dishwasher leaking water, unusual noises, or water not circulating properly.

Filters and Waste Traps

Filters protect pumps from food particles and debris. Commercial units accumulate large amounts of debris, making regular dishwasher filter replacement critical.

Signs of replacement: Clogs, slow drainage, or frequent pump strain.

Door Seals & Gaskets

Heavy-duty doors and gaskets prevent water leaks under high-pressure conditions. Over time, seals can wear, crack, or shrink.

Signs of replacement: Leaks, water pooling around the machine, or reduced cleaning efficiency.

Find out how to replace a commercial dishwasher heating element to restore proper water temperature, improve cleaning performance, and ensure compliance with hygiene standards.

Residential vs. Commercial Dishwasher Parts: What’s Different?

Residential dishwashers focus on convenience and moderate cleaning, while commercial models are built for high-volume, fast, and heavy-duty sanitation. The table below highlights the key differences in features and performance.

|

Features |

Residential Dishwasher |

Commercial Dishwasher |

|

Cleaning Power |

Moderate water pressure, fewer jets |

High-pressure jets for heavy-duty cleaning |

|

Cycle Time |

Standard wash cycles (1–2 hours) |

Rapid cycles (5–15 minutes) for high turnover |

|

Capacity |

Holds 10–16 place settings |

Holds multiple racks, continuous load |

|

Durability |

Designed for occasional use |

Built for continuous, heavy-duty operation |

|

Temperature & Sanitization |

Heats water to normal washing temperature |

High-temp or chemical sanitizing cycles |

|

Automation / Controls |

Simple buttons or digital display |

Advanced programmable cycles, timers, sensors |

|

Racks & Loading Flexibility |

Standard fixed racks |

Adjustable, heavy-duty racks for varied dishware |

|

Energy & Water Efficiency |

Moderate efficiency standards |

Often optimized for water & energy efficiency despite high-volume use |

|

Noise |

Relatively quiet, designed for home use |

Louder due to industrial pumps and high-pressure jets |

Safety Tip: Always ensure commercial dishwashers are installed on plumbing and electrical systems rated for high temperatures and water pressure. Avoid using them on standard residential setups to prevent leaks, burns, or damage to pipes and fixtures.

Troubleshooting Common Issues Related to Dishwasher Parts

Commercial dishwashers are complex machines, and even small problems can disrupt cleaning cycles. This section acts as a practical dishwasher troubleshooting guide, breaking down common parts, their typical causes of failure, and how to troubleshoot them effectively.

Threaded Brass Elbow Connector

Leaks or poor connections in a threaded brass elbow connector usually stem from loose fittings, damaged threads, or worn-out sealing material. Over time, dirt or debris can settle inside the threads, preventing a tight, secure fit. In some cases, the fitting itself may crack, leading to persistent leakage. To troubleshoot, begin by thoroughly drying the connector and inspecting the threads for dirt, old Teflon tape, or signs of wear. Clean the area and apply a fresh layer of Teflon tape before reassembly to ensure a proper seal. If the connector shows visible cracking or severe damage, replacing the elbow is the best long-term solution.

Rinse Solenoid Valve

When the rinse cycle stops unexpectedly or produces weak water flow, the rinse solenoid valve is often the source of the issue. Blockages in the pump, electrical faults within the valve, or insufficient water supply can all interrupt the rinse function. Temperature sensor errors can also prevent the cycle from advancing as intended. Start troubleshooting by checking the pump for clogs and ensuring that water reaches the valve with adequate pressure. Inspect the solenoid valve’s wiring and internal components for faults, and repair or replace any malfunctioning parts. Correcting these issues typically restores consistent rinse performance.

Detergent Pump

Incorrect detergent dispensing generally occurs when the detergent pump is blocked, faulty, or improperly connected. Obstructions within the pump or suction lines can reduce flow and prevent proper dosing during the wash cycle. To troubleshoot, first confirm that the pump’s suction line is securely attached to the detergent container and free of kinks or blockages. Clear any obstructions from the pump and verify that it is receiving the necessary electrical power to operate. If the pump still fails to dispense correctly after these checks, replacing the detergent pump may be required.

Rinse Agent Pump

If the rinse agent pump dispenses during the wrong cycle, the issue typically involves swapped tubes, damaged lines, or a failing pump. When tubing is incorrectly connected or obstructed, the machine may dispense rinse agent at the wrong stage of the wash process. Begin by ensuring the rinse agent tube is connected to the correct port and inspect it for clogs, cracks, or other damage. Test the pump to verify proper operation. If the pump is not functioning correctly, consider a full dishwasher pump replacement to restore accurate cycle-based dispensing.

Suction Tubes / Hoses

Chemical flow problems are commonly caused by swapped, blocked, or damaged suction tubes and hoses. When tubes are kinked, cracked, or clogged, the system cannot draw chemicals correctly, resulting in inconsistent wash or rinse performance. Inspect each tube closely for physical damage or obstructions and ensure every line is connected to the appropriate pump or container. Straighten, clean, reconnect, or replace tubes as necessary to restore proper chemical delivery throughout the system.

Regularly checking these parts and addressing issues promptly ensures your commercial dishwasher continues to operate efficiently, maintains proper chemical dosing, and meets strict sanitation standards.

Check out commercial dishwasher door latch troubleshooting: here's how to fix common issues, ensure a secure seal, and prevent leaks during wash cycles.

How to Identify and Fix Gasket Problems in Your Dishwasher

Gaskets and door seals can wear or crack over time, causing leaks and poor cleaning results, and this section explains when a dishwasher gasket replacement is needed and how to fix common sealing issues.

Signs Your Dishwasher Gasket Needs Attention

Below are the common signs that your dishwasher gasket may be worn or failing.

-

Water pooling around the door or base

-

Steam escaping during cycles

-

Visible cracks, flattening, or gaps in the gasket

-

Unusual noises caused by misdirected water

Steps to Fix Gasket Problems

Follow these steps to repair or replace a faulty dishwasher gasket for optimal performance and leak prevention.

-

Inspect the Gasket: Remove the dishwasher door and examine the gasket closely for cracks, hardening, or deformities.

-

Clean the Gasket: Use a damp cloth to remove food debris, mold, or mineral buildup that can compromise the seal.

-

Replace if Necessary: If the gasket is damaged or worn, replace it with a manufacturer-approved part for your model.

-

Ensure Proper Fit: After installation, press the gasket firmly into its groove and close the door to check for a tight, even seal.

-

Regular Maintenance: Periodically clean and inspect gaskets to prolong their lifespan and prevent leaks.

Pro Tip: On commercial dishwashers, gaskets handle higher pressure and temperature, so check them more frequently to avoid costly water damage and control board issues.

Maintenance Checklist for Longer Dishwasher Performance

Keeping a commercial dishwasher in peak condition ensures consistent sanitation, faster turnaround, and longer equipment life.

Daily Maintenance

-

Pre-rinse and scrape food debris from dishes to prevent blockages in high-capacity systems.

-

Check and clean filters and strainers to maintain proper water flow and avoid buildup.

-

Wipe down door gaskets and exterior surfaces to remove grease and prevent wear.

-

Inspect spray arms for clogs and ensure full rotation during each cycle.

-

Verify chemical levels (detergent, rinse aid, sanitizer) to maintain wash quality.

Weekly Maintenance

-

Deep-clean spray arms by removing them and flushing out mineral or food buildup.

-

Sanitize the interior of the machine, including racks and wash chambers, to maintain hygiene standards.

-

Inspect wash and rinse nozzles for wear or mineral deposits that affect performance.

-

Check temperature settings to ensure the machine reaches proper sanitizing levels.

Monthly Maintenance

-

Descale the dishwasher using manufacturer-approved chemicals to remove hard-water deposits.

-

Inspect pumps, hoses, and seals for leaks, cracks, or unusual wear.

-

Test the door and safety switches to ensure smooth operation and compliance with kitchen safety.

-

Schedule a professional service check to verify that mechanical and electrical components are functioning optimally.

-

Routine maintenance keeps commercial dishwashers efficient, compliant, and reliable during peak service hours.

Conclusion: Keep Your Dishwasher Running at Peak Efficiency

A commercial dishwasher is a critical asset in any food-service operation, and maintaining each component ensures consistent cleaning results, faster turnaround times, and long-term equipment reliability. By understanding how key parts function, identifying early signs of failure, and applying proper maintenance practices, commercial kitchens can prevent common dishwasher problems, significantly reduce downtime, and avoid costly repairs. Staying proactive with inspections and replacements also improves sanitation compliance and overall operational performance.

Key Takeaways

-

Knowing key components improves troubleshooting and cleaning quality.

-

Replacing worn spray arms, pumps, gaskets, and other dishwasher repair parts prevents performance loss.

-

Commercial units require durable, high-pressure parts for continuous use.

-

Early issue detection reduces downtime and repair costs.

-

Routine maintenance supports efficiency, hygiene, and overall reliability.

With proper care, timely troubleshooting, and scheduled maintenance of components such as the dishwasher water inlet valves, commercial dishwashers can deliver reliable performance even in the most demanding kitchen environments. Following these best practices ensures better hygiene, lower operating costs, and smooth, uninterrupted service throughout daily operations.

FAQs

How can I tell if my dishwasher gasket is worn out?

Look for leaks around the door, water pooling, or visible cracks in the gasket. A worn gasket can also cause poor sealing and musty odors.

Why is my dishwasher not cleaning dishes properly?

Clogged spray arms, blocked filters, or low water pressure often reduce cleaning efficiency. Regular maintenance usually fixes most issues.