How to Troubleshoot Lincoln Pizza Oven Problems in Busy Catering Operations

Lincoln pizza ovens are essential in high-volume commercial kitchens, delivering consistent, high-quality pizzas for busy catering operations. Known for their durability, precision, and efficiency, these ovens help streamline workflow and maintain service standards during peak hours. Yet even the most reliable commercial equipment can face issues from temperature fluctuations to ignition failures that disrupt operations and affect revenue. In this blog, we explore the most common Lincoln pizza oven problems, practical troubleshooting strategies, key components to monitor, and preventive maintenance tips to keep your kitchen running smoothly.

How Lincoln Pizza Ovens Downtime Impacts Busy Catering Operations

Lincoln pizza oven downtime can severely disrupt high-volume catering kitchens, especially during peak service hours. Below are the key ways Lincoln pizza oven downtime affects busy catering operations:

-

Reduced Throughput: When a Lincoln pizza oven malfunctions, pizza production slows down. During peak service, hundreds of orders can be delayed, creating bottlenecks that ripple through the kitchen. This can lead to longer wait times, missed deadlines for catering events, and dissatisfied clients.

-

Higher Labor Costs: Staff often have to compensate for the broken oven by adjusting workflows or using smaller, less efficient ovens. These workarounds require extra effort, extend preparation times, and increase labor expenses. Emergency repairs may also come with premium fees, adding further financial strain.

-

Lower Food Quality: Consistent temperature control and even heat distribution are critical for pizza quality. Oven downtime or malfunction can cause uneven cooking, resulting in undercooked or overcooked pizzas. This affects client satisfaction and may harm the kitchen’s reputation for quality.

-

Revenue Loss: Delayed orders, refunds, or cancellations due to equipment failure directly impact revenue. In large catering operations, even brief outages during busy periods can result in significant financial losses, often far exceeding repair costs.

-

Staff Stress: Repeated oven issues increase stress levels, reduce workflow efficiency, and may contribute to higher staff turnover. A well-maintained oven ensures smoother operations, helping staff stay productive, focused, and confident in delivering timely service.

Common Lincoln Pizza Oven Problems in High-Volume Kitchens

In busy commercial kitchens, Lincoln pizza ovens face constant use and high operational demands. Over time, repeated heat cycles, extended run hours, and minimal cooldown periods can lead to problems that impact production, food quality, and safety. Below are the most common issues operators encounter:

Oven Not Heating or Losing Temperature: The oven fails to reach the target temperature, or the temperature drops during operation. Food may cook unevenly, take longer than usual, or remain undercooked. The digital display may show fluctuating or unrealistic temperature readings.

-

Cause: Gas supply issues, closed or partially closed valves, faulty thermostats (gas ovens), or damaged oven heating elements, failed contactors, and electrical supply interruptions (electric ovens).

-

Impact: Reduced product quality, inconsistent cooking, longer service times, and potential delays during peak hours.

Fan or Blower Failures: The oven overheats or shuts down unexpectedly after running for a while. You may hear unusual noises, such as rattling or grinding from fans, or notice uneven internal temperatures. Electronic components may overheat and display warning indicators.

-

Cause: Blown fuses, defective fan motors, worn capacitors, seized blades, or wiring faults.

-

Impact: Safety shutdowns, potential damage to electronics, increased wear on oven components, and reduced lifespan of the equipment.

Ignition or Flame Stability Issues (Gas Ovens): The oven burner fails to ignite, the flame extinguishes unexpectedly, or it flickers irregularly. You may notice an ignition delay or repeated attempts before the burner lights.

-

Cause: Worn igniters, dirty or faulty flame sensors, malfunctioning ignition modules, or failing thermocouples.

-

Impact: Safety hazards from gas buildup, interrupted service, halted production, and delayed food delivery.

Conveyor Belt or Drive Problems: The conveyor belt stops moving, slips, jams, or moves irregularly. Fault codes related to belt motion may appear on the control panel. Food may be partially cooked due to uneven belt speed.

-

Cause: Blown fuses, tripped breakers, failed conveyor motors, defective capacitors, or faulty speed sensors.

-

Impact: Production halts, delayed orders, reduced kitchen efficiency, and possible damage to conveyor components.

Temperature Sensor or Control Display Errors: The oven shows incorrect temperature readings, fluctuates rapidly, or displays error messages on the panel. Heating may stop completely even if the stove seems operational.

-

Cause: Open or shorted sensors, voltage inconsistencies, failing transformers, or electronic board faults.

-

Impact: Cooking errors, inconsistent food quality, service delays, and unexpected downtime.

Overheating and Intermittent Operation: The oven heats inconsistently, shuts down mid-operation, or requires frequent rest periods to avoid overheating. You may notice a strong, hot smell or smoke due to grease accumulation or blocked vents.

-

Cause: Failing blower motors, blocked ventilation pathways, grease buildup, or activation of thermal protection systems.

-

Impact: Production interruptions, accelerated component wear, potential oven damage, and compromised food safety.

Shop now at PartsFe UK to keep your Lincoln ovens running at peak performance. We offer a wide selection of Lincoln replacement parts, including heating elements, control panels, ignition cables, and finger housings, ensuring your commercial kitchen stays reliable and efficient.

How to Troubleshoot Lincoln Pizza Oven Problems

Troubleshooting Lincoln pizza ovens works best when you follow a clear, step-by-step approach. Addressing simple issues first can prevent unnecessary repairs and help keep commercial kitchens running smoothly. Below are the key steps to identify and resolve common Lincoln pizza oven problems:

Step 1: Confirm Power and Gas Supply: Start by ensuring the oven is receiving electricity or gas. Check circuit breakers, fuses, and the main power switch. For gas models, confirm the shutoff valve is fully open and the gas pressure is stable. Many operational issues are caused by supply interruptions rather than internal failures.

Step 2: Inspect Heating Elements or Burners: If the oven powers on but does not heat properly, examine the heat source. Gas burners may become blocked with grease or debris, reducing flame output. Electric heating elements should be checked for visible damage or discoloration. Cleaning or replacing damaged components often restores normal heating.

Step 3: Check Temperature Controls: Accurate temperature control is essential for consistent baking. Compare the oven’s display reading with an external thermometer. If temperatures do not match, the thermostat or temperature sensor may be faulty and require recalibration or replacement.

Step 4: Examine the Ignition System: For gas ovens that fail to ignite, inspect the igniter and flame sensor. Dirt or wear can prevent proper ignition. Cleaning these components may resolve the issue, but worn parts should be replaced to ensure safe and reliable operation.

Step 5: Verify Fans and Airflow: Blocked vents or faulty fans can cause overheating or uneven baking. Inspect Lincoln pizza oven parts related to airflow to maintain consistent cooking.

Step 6: Inspect Moving and Mechanical Parts: Check conveyor belts, motors, and rotating components for wear or misalignment. Loose or worn parts can slow production and cause inconsistent cooking results. Timely replacement helps avoid unexpected breakdowns during peak hours.

Step 7: Review Controls and Electronics: If the control panel is unresponsive, perform a reset and inspect wiring for loose or damaged connections. Ongoing error messages or display issues may indicate a failing control board that needs professional attention.

Step 8: Record and Monitor Problems: Keep a maintenance log of issues and repairs. Tracking repeated problems helps identify underlying causes and supports preventive maintenance, reducing long-term downtime.

|

Disclaimer: The troubleshooting steps above are for informational purposes only. Always follow Lincoln pizza oven manufacturer guidelines and safety instructions. For complex repairs, electrical or gas issues, or if you’re unsure, consult a certified technician to ensure safe and proper operation. |

Check out oven heating element replacement made easy: identify, fix and maintain like a pro, a quick guide to spotting, replacing, and maintaining oven heating elements

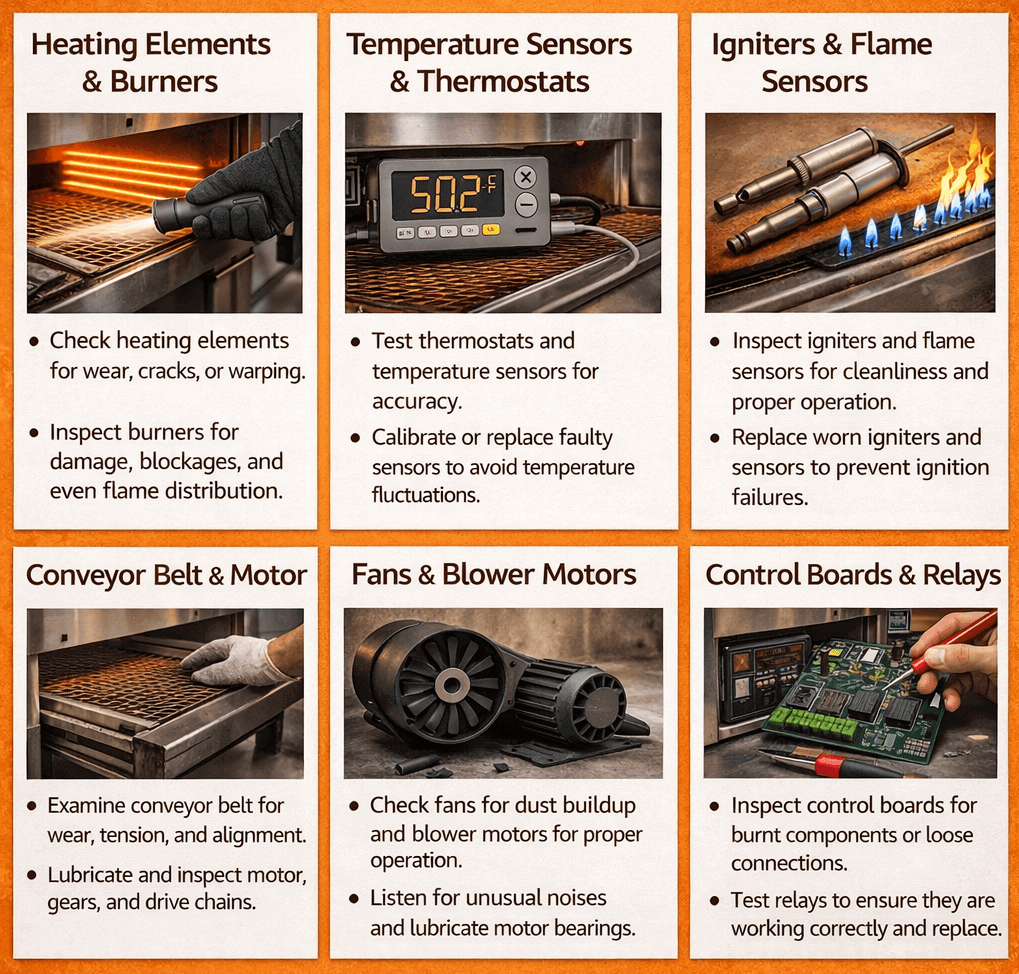

Essential Lincoln Pizza Oven Parts to Check During Repairs

During repairs, always inspect critical components such as heating elements, burners, temperature sensors, conveyor systems, fans, and control boards. These parts directly impact cooking consistency, safety, and uptime in commercial kitchens. Refer to the image below for a visual overview of the key Lincoln pizza oven components that require routine inspection and maintenance.

|

Caution: Always ensure the oven is powered off and cooled before performing maintenance or inspections to prevent burns or electric shock. |

Find out how to replace a commercial oven light bulb: the ultimate guide for safe and easy installation.

Summary: Keeping Lincoln Pizza Ovens Efficient in Catering Kitchens

In busy catering kitchens, Lincoln pizza ovens are crucial for delivering consistent, high-quality pizzas. Regular inspections, timely repairs, and proper cleaning help prevent overheating, uneven cooking, and mechanical failures. Following manufacturer guidelines and addressing issues early ensures safe operation, reduces downtime, and maintains smooth kitchen workflows.

Key Takeaways

-

Inspect heating elements, burners, fans, and conveyor belts regularly to catch wear or damage early and prevent unexpected failures.

-

Verify temperature sensors and thermostats to maintain accurate readings and ensure consistent cooking results.

-

Address recurring issues promptly to avoid extended downtime that can disrupt service during peak hours.

-

Seek professional help for gas, electrical, or complex faults to ensure safety and prevent further damage.

-

Clean ovens thoroughly to remove grease buildup, maintain airflow, and reduce overheating risks.

-

Keep a maintenance log to track repairs and problems, helping identify patterns and plan preventive maintenance effectively.

FAQs

How to change the temperature on a Lincoln pizza oven?

Use the control panel to adjust the set temperature. For models with digital displays, press the up or down arrows to select the desired temperature. Always allow the oven to stabilize before cooking to ensure even heat distribution.

What’s the best way to clean a Lincoln Impinger pizza oven?

Turn off and cool the oven first. Remove crumbs and debris, wipe interior surfaces with a damp cloth, and clean the conveyor belt using manufacturer-approved cleaners. Avoid abrasive tools to prevent damage.

How to put a belt on a Lincoln pizza oven?

Ensure the oven is powered off. Release the tension on the conveyor system, slide the belt onto the rollers, and realign it according to the manual. Re-tension the belt evenly to avoid slippage.

Is it cheaper to repair or replace an oven?

Minor issues like heating elements or belts are usually cheaper to repair. Replacement may be more cost-effective only when multiple components fail, or the oven is outdated, considering labor, downtime, and energy efficiency.