How to Troubleshoot Conveyor Belt Problems in Catering Equipment

Within busy commercial kitchens and catering environments, conveyor belts are indispensable elements, used for automating food preparation, cooking, and handling tasks with precision and efficiency. Whether it’s a conveyor belt toaster, a conveyor belt oven, or another vital device, swift operation and reliable performance hinge on the smooth functioning of these intricate systems. When issues arise, downtime can cause significant disruption and impact service quality, making it crucial for catering professionals to understand and undertake effective conveyor belt troubleshooting practices. This guide will walk you through all aspects of managing and maintaining conveyor belts in catering applications.

Understanding the Role of Conveyor Belts in Catering Equipment

Conveyor belts perform essential functions in many types of catering equipment, ensuring food moves seamlessly through each stage of preparation or cooking. Their correct operation underpins kitchen efficiency.

-

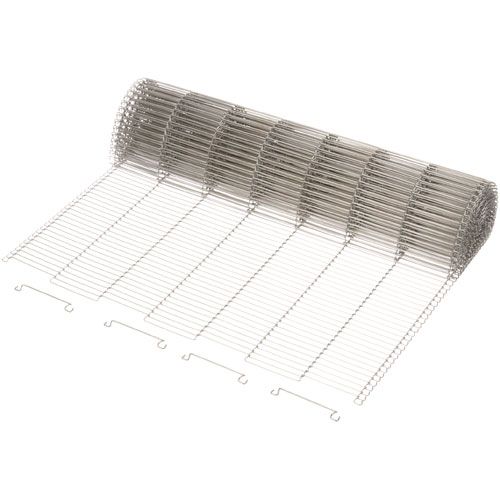

In the realm of hospitality, conveyor belts such as the chain conveyor belt, wire conveyor belt, or stainless steel conveyor belt are integral to devices like the conveyor belt oven and conveyor belt toaster.

-

They automate repetitive tasks, allowing precise timing, temperature control, and minimal human intervention, vital attributes for high-volume service.

The conveyor belt for the food industry is specifically engineered for hygiene, durability, and compliance with food safety regulations, ensuring consistency and reliability.

Common Causes of Conveyor Belt Malfunctions

Understanding root causes of failure is the first step towards effective conveyor belt troubleshooting. The most prevalent problems encountered with conveyor belts in the food sector include:

-

Misalignment: When the conveyor belt assembly drifts off-centre, possibly due to worn guide rails or incorrectly set conveyor end stops.

-

Slippage: Caused by a worn conveyor belt drive motor, loose tension, or greasy build-up impeding traction.

-

Belt Damage: Fraying or breakage of a wire conveyor belt or corrosion in a stainless steel conveyor belt can halt an otherwise efficient operation.

-

Obstructions: Jammed items or residue can block a conveyor rod or sections of the chain conveyor belt, resulting in stoppages.

-

Motor Issues: Failure, overheating, or erratic speeds from the motor conveyor belt disrupt normal functions.

Failures may be indicated by uneven product movement, abnormal noises, overcooking or undercooking in the conveyor belt oven, or products jamming inside a conveyor belt toaster.

Step-by-Step Troubleshooting Guide for Conveyor Belt Issues in Catering Equipment

Resolving technical issues systematically minimises downtime and prevents further equipment damage. Follow this guide for effective conveyor belt troubleshooting in catering settings.

1. Conduct a visual inspection

Begin with a close examination of the entire conveyor belt assembly.

-

Check for visible wear, tears, or contamination on the conveyor belts and inspect connections at the conveyor rod, guides, and conveyor end stops. Examine whether the chain conveyor belt or wire conveyor belt sections are warped, broken, or out of place.

-

Ensure the stainless steel conveyor belt hasn’t buckled due to thermal stress, particularly in high-heat zones like the conveyor belt oven.

2. Listen for unusual noises and observe function

-

Run the conveyor belt for the food industry and pay attention to abnormal sounds. Grinding, rattling, or squeaking can identify points of friction or component failure within the chain or drive system. Persistent belt noise in a conveyor belt toaster or oven should never be ignored.

3. Test belt alignment and tension

-

Misalignment or slack is a frequent culprit. Ensure the conveyor end stops are adjusted correctly and all guides are intact. Adjust tension to manufacturer guidance, as an overly tight wire conveyor belt will accelerate wear, while a loose belt may slip off or fail to carry items efficiently.

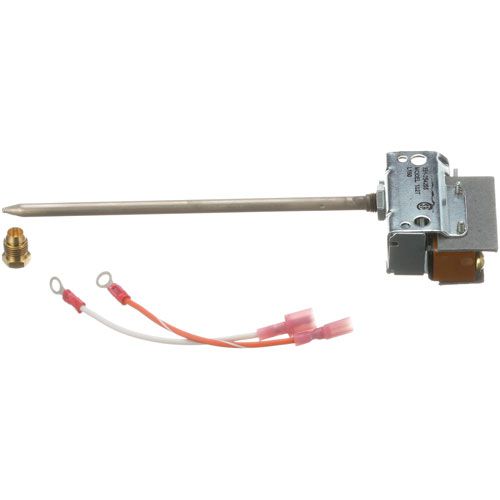

4. Check the drive motor and controls

-

Inspect the conveyor belt drive motor for overheating, vibrations, or inconsistent running, which may indicate internal bearing or wiring issues.

-

For machines using a motor conveyor belt, reset control panels and check all power, speed, and direction settings. Faulty relays or damaged wiring can cause intermittent stalling or erratic movement.

5. Remove obstructions and clean thoroughly

-

Clear any jammed food pieces, burnt-on residue, or grease, particularly from moving elements like the conveyor rod or between links of the chain conveyor belt. In the conveyor belt toaster, crumbs or melted cheese can accumulate and cause blockages, so regular cleaning is essential. Always isolate power before cleaning.

6. Run test cycles

-

After addressing potential issues, run the machine empty to observe performance. Ensure the conveyor belt troubleshooting steps have restored smooth operation, with even motion and consistent product output.

Signs to Replace Conveyor Belt or Motor

Recognising when replacement, rather than repair, is necessary is vital to avoid hazardous faults and unplanned downtime in your kitchen.

-

Persistent malfunctions: Frequent repairs with little or no improvement.

-

Visible Wear: Fraying, holes, melted sections, or broken links in a wire conveyor belt or chain conveyor belt.

-

Reduced performance: Slower speeds, inconsistent heating in a conveyor belt oven, or uneven toasting in a conveyor belt toaster.

-

Motor issues: Overheating, excessive noise, or failure to start in a motor conveyor belt.

Always use OEM parts or ones certified for the conveyor belt for the food industry, as low-quality substitutes may fail prematurely.

Choosing the Right Conveyor Belt and Motor for Catering Equipment

Selecting appropriate components is essential not just for reliable operation, but for food safety and compliance in the catering sector.

-

Material matters: For greasy or moist applications, a stainless steel conveyor belt resists corrosion and provides robust hygiene. A wire conveyor belt may be ideal for bakery lines needing airflow, while a chain conveyor belt delivers heavy-duty performance in more industrial kitchen settings.

-

Motor choices: The conveyor belt drive motor must offer power, reliability, and low energy use. Confirm compatibility with your existing equipment and intended load. Always ensure the motor conveyor belt is sourced from a recognised supplier, attuned to local standards.

-

Customisation and sizing: Obtain the right width, length, and construction for your conveyor belt assembly, or undersized units will lead to rapid wear and operational headaches.

Ultimate Restaurant Equipment Supply Guide: Proven Sourcing Tips for Superior Quality Parts

Safety Guidelines for Working with Conveyor Belts in Commercial Kitchens

Proper safety protocols are non-negotiable when handling powerful, high-speed catering equipment. Protect your team, your equipment, and your compliance record at all times.

-

Isolation before maintenance: Always disconnect from power before inspecting or undertaking repairs on the conveyor belt, conveyor rod, or motor conveyor belt.

-

Wear personal protective equipment (PPE): Use gloves, safety glasses, and suitable clothing to protect against moving parts and hot surfaces.

-

Training: Ensure all staff are trained in the correct use of conveyor belts, aware of emergency stops, and understand routine conveyor belt troubleshooting procedures.

-

Frequent testing: Regularly test the operation of all emergency stops, alarms, and safety cut-offs.

-

Risk assessments: Conduct and document regular risk assessments for all applications involving conveyor belts in food environments.

The Ultimate Guide to Commercial Kitchen Layout: Do’s & Don’ts

Preventive Maintenance Practices for Conveyor Belts

Proactive maintenance ensures catering equipment runs smoothly, minimizes costly breakdowns, and extends the lifespan of conveyor belts.

|

Practice |

Details |

|

Routine Inspections |

|

|

Lubrication and cleaning |

|

|

Tension and alignment |

|

|

Electrical safety |

|

Conveyor belts form the basis of efficient, large-scale food preparation and cooking operations throughout the catering industry. Prompt identification and resolution of faults, paired with regular preventive care and observance of safety standards, guarantee their longevity and optimal performance. By mastering these conveyor belt troubleshooting steps and maintenance guidelines, you’ll keep your kitchen running smoothly, safeguard your personnel, and uphold the highest standards for customers and regulators alike. PartsFe UK offers a wide range of commercial kitchen electrical accessories from trusted manufacturers, including wiring, fuses, thermostats, heating elements, motors, switches, and relays. Browse our collection of electrical hardware to meet the needs of your commercial kitchen equipment.

FAQs

What issues might a change in the conveyor belt cause?

A change in the conveyor belt can cause misalignment, increased wear on conveyor belt parts, reduced efficiency, or unexpected downtime.

What are the safety requirements for conveyor belts?

Safety requirements for conveyor belts include proper guarding, emergency stop controls, regular inspection of conveyor belt parts, and compliance with industry safety standards.