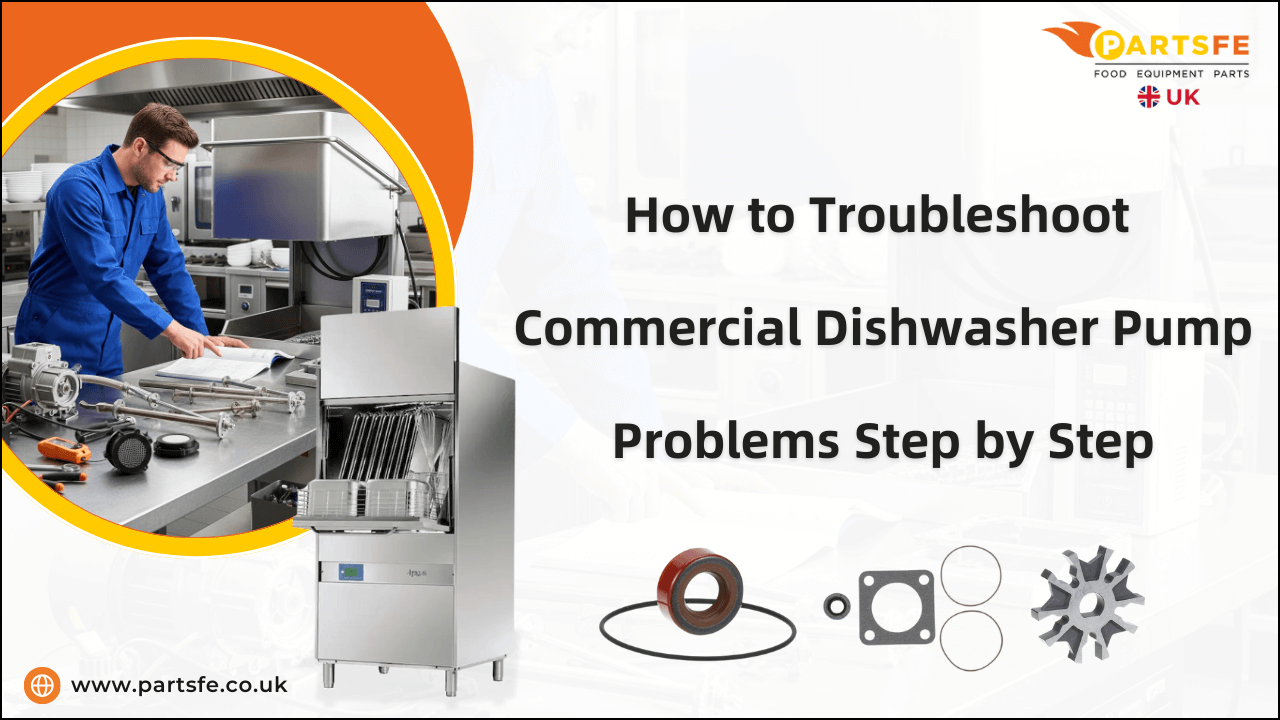

How to Troubleshoot Commercial Dishwasher Pump Problems: Step by Step Guide

Commercial dishwashers are essential for maintaining efficiency and hygiene in restaurants, hotels, and other foodservice operations. The dishwasher pump is a critical component, responsible for circulating water to ensure thorough cleaning. When pump issues occur, they can lead to reduced cleaning performance and increased maintenance costs. Understanding how commercial dishwasher pumps operate, recognizing common signs of failure, and knowing how to troubleshoot problems are crucial for operators and maintenance staff. This dishwasher pump troubleshooting guide provides clear instructions on diagnosing pump issues, identifying their causes, and performing repairs or replacements effectively. Following these procedures will help maintain consistent performance and extend the service life of your commercial dishwasher.

Understanding How Commercial Dishwasher Pumps Work

A commercial dishwasher pump is a motor-driven component that moves water through the system at high pressure. Unlike residential units, commercial dishwashers operate for extended hours and handle large volumes of heavily soiled dishware, which places significant demand on the pump assembly.

Dishwasher Pump Work Cycle

The pump cycle is essential for consistent cleaning and sanitation. The process works as follows:

-

Heating and Circulation: The wash pump circulates water through the spray arms after it reaches the required temperature, effectively removing food particles and debris from dishes. If the dishwasher wash pump not working, cleaning performance drops significantly.

-

Draining: Once the wash cycle is complete, the drain pump removes dirty water. Problems here often lead to commercial dishwasher not draining water complaints

-

Rinsing and Sanitizing: Fresh water refills the dishwasher, and the rinse pump delivers high-pressure water to thoroughly rinse and sanitize all items.

Any disruption in this cycle can result in commercial dishwasher water circulation issues and poor hygiene outcomes.

Key Pump Types in Commercial Dishwashers

Commercial dishwashers rely on several pump types to manage water flow, drainage, pressure, and chemical delivery. Each pump plays a specific role to ensure proper cleaning, rinsing, and sanitation:

|

Pump Type |

Purpose in the Dishwasher |

Common Technology |

|

Wash/Circulation Pump |

Delivers high-pressure wash water |

Centrifugal |

|

Drain Pump |

Pumps out wastewater |

Centrifugal/submersible |

|

Rinse Pump |

High-pressure rinsing |

Centrifugal |

|

Booster Pump |

Increases the supply water pressure |

Centrifugal |

|

Detergent/Chemical Dosing Pump |

Delivers detergent & rinse aid |

Peristaltic (positive-displacement) |

|

Recirculation Pump |

Reuses and filters wash water |

Centrifugal |

Is your commercial dishwasher keeping up with the demands of a busy kitchen? PartsFe UK offers a wide range of parts for restaurant equipment designed to support smooth, uninterrupted service. We supply high-quality dishwasher replacement parts, including timers, hoses, and door latches, built for reliability and performance. Our inventory features trusted brands such as Jackson, Hobart, Ultrafryer, and Amana to meet professional kitchen standards.

Common Signs of Commercial Dishwasher Pump Problems

Recognizing signs of a bad dishwasher pump early helps to avoid more serious failures. Common symptoms include:

-

Ineffective Cleaning: Dishes that still have food particles or appear spotted or streaked after a cycle may indicate that the circulation pump is not providing adequate water pressure.

-

Delayed or Incomplete Cycles: Longer-than-normal wash or drain times can be a sign that the pump is not maintaining proper water flow throughout the system.

-

Wash Pump Runs Continuously: If the wash pump keeps running even after the wash cycle is complete, it may indicate a faulty pressure switch, a stuck relay, or a control board issue.

-

Intermittent Operation: Pumps that stop and start unexpectedly may be suffering from overheating, electrical problems, or internal motor wear.

-

Error Codes: Modern commercial dishwashers are equipped with diagnostic systems. Pump-related error codes should be addressed promptly to prevent system shutdowns.

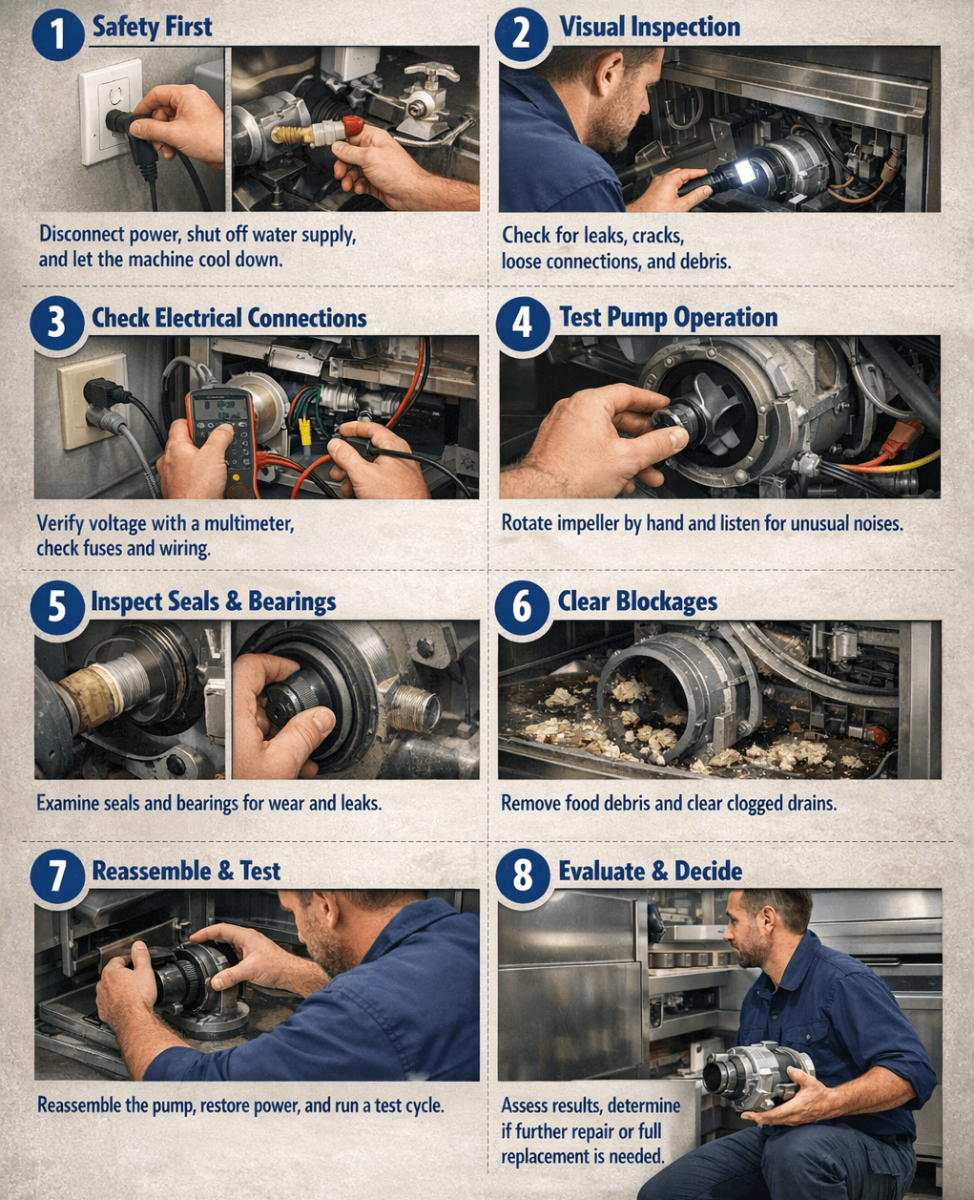

Step-by-Step Process to Troubleshoot a Commercial Dishwasher Pump

Proper troubleshooting requires a systematic approach. The following steps provide a structured method to identify and resolve pump problems safely and effectively.

Main Causes of Commercial Dishwasher Pump Failures

Regular inspection of related dishwasher parts can help detect early signs of wear or damage before major issues occur. Below are the main factors that commonly lead to commercial dishwasher pump problems:

-

Debris Buildup: Food particles, grease, and leftover residues can accumulate in filters, drains, and pump components, causing blockages that strain the pump and reduce efficiency.

-

Wear and Tear: Continuous use over time can wear out key pump parts such as motors, seals, and impellers, potentially leading to leaks, reduced pressure, or complete failure.

-

Hard Water: Calcium and magnesium in hard water can form scales inside the pump and pipes, restricting water flow and accelerating component deterioration.

-

Improper Loading: Overcrowding dishes or using excessive/incorrect detergent can create excess strain on the pump, affect water circulation, and cause premature failure.

-

Electrical Issues: Irregular voltage, damaged wiring, or malfunctioning control components can overwork the pump motor, leading to reduced efficiency or premature failure.

-

Vibration Damage: Persistent vibration or misaligned rotating parts can loosen internal components, wear out bearings, and cause cracks in the pump housing, shortening the pump’s lifespan.

Check out how to install a dishwasher drain hose: the ultimate guide for easy, leak-free installation tips

When to Repair or Replace a Commercial Dishwasher Pump

Here are the most common conditions affecting commercial dishwasher pumps, along with clear guidance on whether repair or replacement is the appropriate solution. This condition-based overview helps technicians and operators quickly assess pump issues, minimize downtime, and ensure safe, efficient dishwasher operation.

|

Condition |

When to Repair |

When to Replace |

|

Food debris, grease, or foreign objects blocking water flow |

Clean the pump housing and impeller thoroughly |

Replace the pump if blockage has caused internal damage |

|

Minor water leakage at pump seals or fittings |

Replace worn seals, gaskets, or tighten fittings |

Replace the pump if leaks persist after seal replacement |

|

Reduced water pressure or weak circulation |

Remove scale buildup and clean pump components |

Replace the pump if performance does not improve |

|

Mineral scale buildup from hard water |

Descale and clean the affected pump parts |

Replace the pump if scaling has damaged internal components |

|

Unusual vibration or noise during operation |

Secure loose fittings or realign the pump |

Replace the pump if bearings or internal parts are worn |

|

Impeller wear or minor damage |

Replace the impeller only |

Replace the full pump assembly if the impeller damage is severe |

|

Intermittent electrical connection issues |

Repair or secure wiring connections |

Replace the pump motor if the electrical failure continues |

|

Pump runs but does not move water |

Inspect and clear obstructions; check the impeller |

Replace the pump if the motor spins, but circulation fails |

|

Pump motor overheating |

Improve ventilation and check load conditions |

Replace the pump motor if overheating persists |

|

Visible corrosion on the pump housing |

Clean and treat light corrosion |

Replace the pump if corrosion compromises the structural integrity |

Find out how to replace a commercial dishwasher heating element safely and correctly.

Conclusion: Keeping Your Commercial Dishwasher Pump Running Efficiently

Maintaining your commercial dishwasher pump in optimal condition is crucial for consistent cleaning performance and extending the appliance’s lifespan. Regular inspections, proper dish-loading, and timely repairs help prevent minor issues from developing into major problems. Recognizing the early signs of pump failure and knowing how to troubleshoot, clean, or replace components ensures smooth and efficient operation in any commercial kitchen.

Key Takeaways:

-

Inspect and clean the pump, filters, and surrounding components regularly.

-

Address pump issues promptly to prevent major failures.

-

Follow proper dish-loading practices and use recommended detergents to reduce strain.

-

Use manufacturer-approved parts for repairs or replacements.

-

Monitor water quality and hardness to prevent scale buildup.

-

Always follow safety precautions and use the correct tools during maintenance.

By following a structured approach to pump maintenance and repair, operators can minimize operational disruptions, protect hygiene standards, and optimize performance. Using the right tools, adhering to safety precautions, and relying on manufacturer-approved parts are essential for maintaining reliability and longevity.

FAQs

How do I clean the dishwasher pump?

Turn off power and water, remove access panels, and carefully clean the pump and impeller to remove debris or buildup. Replace any worn seals, then reassemble and test the pump.

How do I restart the dishwasher pump?

After clearing any blockages, ensure the dishwasher is powered, and the water supply is on. Reset the machine following the manufacturer’s instructions and run a short test cycle to confirm normal operation.

How do I unblock the dishwasher drain pump?

Switch off power and water, access the drain pump and hoses, and remove any debris or clogs. Reassemble the components and test the drainage to ensure smooth water flow.

How much does it cost to replace a dishwasher pump?

Replacement pumps for commercial dishwashers typically cost between $100 and $400 for parts. Always use manufacturer-approved pumps to ensure compatibility and optimal performance.