How to Choose Commercial Fryer Baskets for High-Performance Restaurant Kitchens

In high-performance restaurant kitchens, every component of the cooking process plays a role in speed, consistency, and food quality. While commercial fryers often receive attention for their capacity, recovery time, and energy efficiency, commercial fryer baskets are just as critical to daily operations. The right fryer basket can improve cooking efficiency, ensure consistent results, enhance safety, and extend equipment lifespan. Conversely, poorly chosen baskets can slow service, compromise food quality, and increase maintenance costs.

This guide explains how to choose the best fryer baskets for demanding restaurant environments. It covers what fryer baskets are, why they matter, the types available, how fryer basket sizes, materials, and designs influence performance, and what to consider for safety, maintenance, and long-term durability.

What Are Commercial Fryer Baskets and Why Do They Matter in High-Performance Restaurant Kitchens?

A commercial fryer basket is a specialized metal container used to hold food while it is fried in hot oil. Unlike standard consumer-grade baskets, commercial baskets are built for continuous, high-temperature use in fast-paced, high-volume kitchens. They are engineered to withstand repeated exposure to hot oil and rigorous daily operations, making them essential tools in professional culinary environments. Below are the four key benefits of commercial fryer baskets in high-performance kitchens:

-

Cooking Efficiency: In busy restaurant operations, commercial fryer baskets allow staff to cook large batches quickly without overcrowding the fryer. Properly loaded baskets maintain consistent oil temperatures, reducing cooking time and preventing unevenly fried food.

-

Food Consistency: Well-designed baskets ensure even heat distribution across all items, producing uniform browning and texture. This consistency is crucial for maintaining menu quality and customer satisfaction.

-

Safety: High-quality baskets are engineered to minimize oil splashes and reduce the risk of burns, which is critical in fast-moving kitchen environments. Ergonomic handles and secure construction help prevent accidents during frying and handling.

-

Durability: Commercial-grade materials, including stainless steel fryer baskets, resist warping and corrosion.

Keep your kitchen running smoothly with PartsFe UK’s durable commercial fryer baskets, including basket hanger, filter sheets, and triple baskets (14-3/4" x 5-7/8") compatible with trusted brands like Pitco, Frymaster, and Anets.

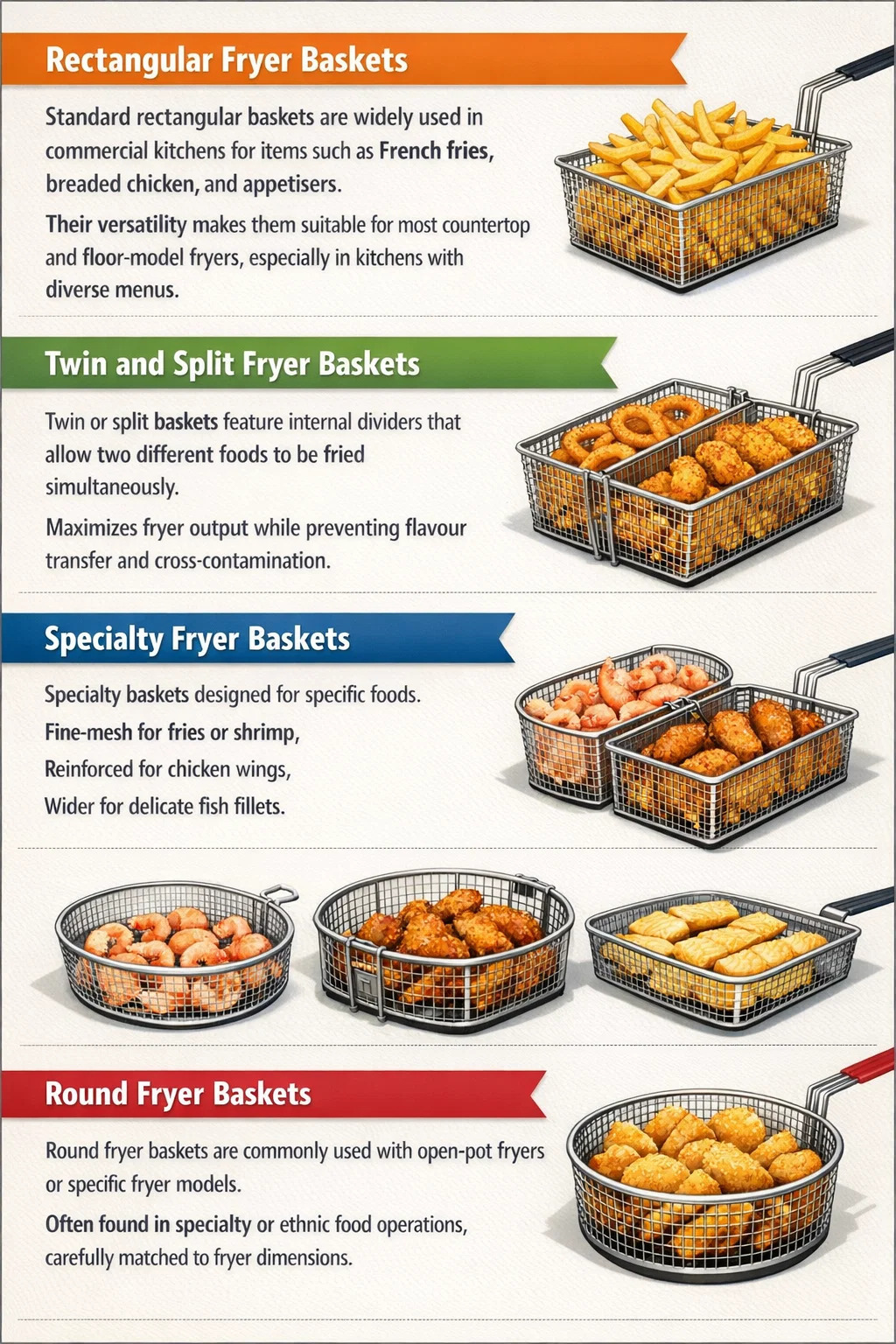

Types of Commercial Fryer Baskets for Different Restaurant Frying Needs

Different menus and fryer configurations require different basket styles. Selecting the correct type ensures optimal cooking performance and efficient use of fryer capacity.

How Do Fryer Basket Size, Material, and Design Affect Cooking Speed and Food Quality?

In commercial kitchens, the choice of fryer basket is more than a simple equipment decision; it directly impacts cooking efficiency, oil performance, and food quality. Basket size, material, and design features determine how quickly food cooks, how evenly it browns, and how much oil is absorbed. Selecting the right combination ensures consistent results, faster service, and reduced waste.

Fryer Basket Comparison: Size, Material, and Design

Below is a concise comparison of the main fryer basket factors, their advantages, disadvantages, and ideal uses in commercial kitchens:

|

Category |

Type / Feature |

Advantages |

Disadvantages |

|

Size |

Small |

Precise cooking, quick oil recovery, and good control for delicate items |

Lower throughput, more labor, limited volume |

|

Medium |

Balanced efficiency, versatile, consistent browning |

Moderate capacity limits, slightly slower for bulk orders |

|

|

Large |

High throughput, faster service, time-efficient |

Risk of overcrowding, slower oil recovery, and less precision |

|

|

Material |

Stainless Steel |

Durable, corrosion-resistant, and even heat |

Higher initial cost |

|

Chrome-Plated |

Lower cost, adequate heat |

Surface wears over time, reducing durability |

|

|

Coated / Non-Stick |

Prevents sticking, easy cleaning |

Less durable, coating may degrade |

|

|

Design |

Mesh / Perforations |

Improves oil flow, retains fragile foods |

Small holes slow cooking, large holes may lose food |

|

Shape & Fit |

Even heat distribution, space-efficient |

Poor fit leads to uneven cooking |

|

|

Handles |

Heat-resistant, ergonomic |

Slightly bulky |

|

|

Reinforced Frame |

Prevents warping, maintains circulation |

Slightly heavier |

Check out commercial deep fryer filters 101: when and how to replace them to keep your oil clean, maintain fryer efficiency, and ensure consistent food quality.

What Should Restaurants Consider for Safety, Maintenance, and Long-Term Durability?

Choosing the right fryer basket goes beyond size, material, or design. In high-performance restaurant kitchens, safety, maintenance, and longevity are equally critical. Considering the factors listed below ensures that baskets continue to perform efficiently while minimizing risks and operational costs.

Safety Considerations:

Ergonomic handles, splash guards, and a secure fit help prevent burns and accidents in fast-paced kitchens. Choosing the right safety features ensures staff protection while maintaining efficient frying operations.

-

Ergonomic Handles: Handles should provide a secure grip, even when wet or oily, to reduce the risk of spills and burns. Some baskets come with insulated or coated handles for added protection.

-

Splash Guarding: High-quality baskets are engineered to minimize hot oil splatter. Properly designed mesh and reinforced edges prevent accidents, protecting kitchen staff from injuries.

-

Secure Fit: Baskets must fit snugly within the fryer. Loose baskets can tip or drop food into the oil, increasing the risk of accidents.

Maintenance and Cleaning

Baskets should be easy to clean, dishwasher-compatible, and designed for efficient oil drainage. Proper maintenance extends basket life and supports consistent food quality.

-

Ease of Cleaning: Stainless steel and coated baskets are easier to clean, resist staining, and do not retain food particles. Quick and efficient cleaning reduces downtime during peak hours.

-

Dishwasher Compatibility: Some commercial fryer baskets are compatible with commercial dishwashers, streamlining cleaning processes and maintaining hygiene standards.

-

Oil Management: Proper basket design allows oil to drain efficiently, minimizing waste and extending the life of cooking oil.

Durability and Long-Term Investment

High-quality, reinforced baskets resist warping, corrosion, and heavy use in high-volume kitchens. Selecting compatible, durable baskets lowers replacement costs and ensures consistent cooking performance.

-

Material Quality: Investing in stainless steel or reinforced baskets prevents warping, corrosion, or deformation over time, which is especially important for high-volume restaurant frying.

-

Frame Reinforcement: Heavy-duty frames help maintain the shape of baskets even under repeated use, ensuring even cooking and consistent food quality.

-

Replacement and Compatibility: Understanding deep fryer basket replacement options and fryer basket compatibility is crucial. Choosing baskets that match your fryer models reduces costs and downtime associated with repairs or replacements.

Learn how to pick the perfect deep fryer machine for a commercial kitchen and ensure efficient, consistent, and high-volume cooking.

Conclusion: How Can the Right Commercial Fryer Basket Improve Consistency and Kitchen Efficiency?

Selecting the right commercial fryer basket ensures even cooking, faster service, and safer operations. Properly sized, durable baskets like stainless steel or heavy-duty models, with ergonomic handles and commercial kitchen fryer accessories, support high-volume kitchens while minimizing maintenance and downtime.

Key Takeaways:

-

Correct fryer basket sizes improve cooking speed and temperature stability.

-

Durable materials, including stainless steel fryer baskets, ensure long-lasting performance.

-

Safety features like ergonomic handles reduce burn and spill risks.

-

Compatibility with fryers supports efficient, high-volume operations.

-

Using fast food fryer baskets or specialty baskets lowers maintenance time and ensures consistent food quality.

Durable, easy-to-clean baskets also lower maintenance time and costs while supporting efficient oil management. Choosing baskets compatible with your fryer models ensures smooth operations and helps maintain high-volume kitchen productivity.

FAQs

Which frying basket material is best?

Stainless steel is the preferred choice for commercial kitchens because it is durable, resists corrosion, and provides even heat distribution, ensuring consistent frying results.

What are the different types of frying baskets?

Frying baskets come in rectangular, round, twin/split, and specialty designs, each suited for different foods and fryer configurations to optimize cooking efficiency.

What is the most important factor to consider when purchasing a deep-fat fryer?

Key factors include fryer capacity, oil recovery time, and compatibility with your menu and kitchen volume to ensure consistent cooking and efficient operations.

What are the three rules to always follow when using a deep fryer?

Always avoid overcrowding the basket to ensure even cooking, use proper safety equipment to prevent burns, and maintain clean oil at the correct temperature for consistent, high-quality frying.