How to Troubleshoot a Henny Penny Fryer: Expert Tips for Smooth Operation

Keeping a henny penny fryer in peak condition is essential for any commercial kitchen aiming for consistent, high-quality fried foods. With busy service periods and tight margins, downtime due to unexpected malfunctions can be costly not only in repair expenses but also in lost revenue and frustrated customers. That’s why proactive henny penny fryer maintenance and swift henny penny fryer troubleshooting are vital. In this comprehensive guide, we’ll explore the anatomy of henny penny fryers, pinpoint common issues, and walk you through step-by-step diagnostic procedures.

Understanding Your Henny Penny Fryer

Every successful repair starts with knowing your equipment inside and out. A henny penny fryer features robust construction designed for heavy commercial use. Key components include:

-

Casters: Provide mobility for cleaning and repositioning. Locking casters keep the unit firmly in place during operation.

-

Commercial deep fryer filters: Trap fine food particles to extend oil life and maintain consistent frying quality.

-

Commercial fryer baskets: Engineered for quick loading and draining, these baskets must fit precisely to prevent oil spillage and ensure even cooking.

-

Deep fryer conversion kits: Allow you to switch between gas and electric models or retrofit filtration systems, maximizing versatility in your kitchen.

-

Deep fryer pots: The main frypot holds cooking oil; choosing the correct capacity and material (stainless steel or aluminized steel) affects heat retention and durability.

-

Deep fryer temperature controls: Digital or analog controllers regulate oil temperature to within one or two degrees, critical for food consistency and safety.

-

Fryer filter hoses: Durable, food-grade hoses channel oil from the frypot to the filtration unit; cracks or clogs here can lead to filter bypass and oil contamination.

-

Fryer thermocouples: Sensors that relay real-time temperature readings to the control board; a failed thermocouple can cause overheating or underheating.

-

Heating elements: Immersed directly in the frypot, these elements convert electrical energy into heat. Monitoring for scale build-up and continuity is key.

-

High limit switches: Safety devices that cut power if oil temperature exceeds safe thresholds, preventing fire hazards and equipment damage.

Familiarize yourself with common henny penny fryer parts locations by referencing the unit’s schematic diagram. Having a spare set of genuine Henny Penny parts, such as gaskets, valves, and high-limit switches, on hand can dramatically reduce repair time.

Common Issues Requiring Henny Penny Fryer Troubleshooting

Even the sturdiest henny penny fryers can encounter hiccups. These are the most frequent problems:

-

Fryer not heating properly: Often due to a faulty heating element or thermostat failure.

-

Uneven cooking or inconsistent oil temperature: Caused by clogged filters, sediment buildup, or malfunctioning sensors.

-

Oil filtration not working: Leads to rapid oil degradation, off-flavors, and shortened oil life.

-

Electrical malfunctions: Tripped breakers, burned wiring, or control board failures.

Note down error codes displayed on the panel, any unusual sounds or smells, and check the service log for recurring issues. A systematic approach minimizes guesswork and helps isolate the root cause more efficiently.

Step-by-Step Guide to Henny Penny Fryer Troubleshooting

Follow these steps to diagnose and address most fryer problems:

Check the power supply and control settings

-

Ensure the unit is receiving adequate voltage.

-

Verify that timers, temperature settings, and safety interlocks are correctly set.

Inspect thermostats, heating elements, and wiring

-

Remove the back panel and examine for discoloration or burn marks.

-

Use a multimeter to test continuity in heating coils and high-limit switches.

Test oil sensors and filters

-

Clean or replace clogged filtration cartridges.

-

Calibrate oil-level sensors per manufacturer specs.

Replace worn or damaged components

-

Swap out any suspect Henny Penny fryer parts, gaskets, element assemblies, or thermocouples with genuine Henny Penny replacement parts.

-

Retest the unit after each swap to confirm the issue is resolved.

Document each step and measurement. This record becomes invaluable for future repairs and can highlight patterns pointing to underlying design or usage issues.

Importance of Using Genuine Henny Penny Replacement Parts

When a component fails, reaching for authentic Henny Penny replacement parts pays dividends:

-

Reliability: OEM parts are engineered to exact tolerances, ensuring proper fit and function.

-

Safety: Non-genuine components may not meet UL or NSF certifications, risking electrical hazards or contamination.

-

Warranty protection: Using unofficial parts can void your fryer’s warranty and lead to higher long-term costs.

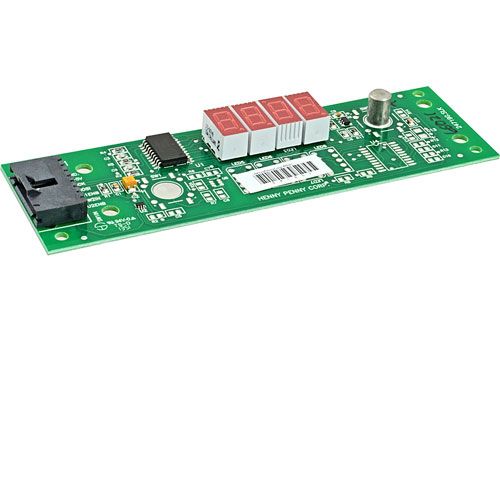

Commonly replaced items include henny penny fryer parts like high-limit switches, heating element, control board modules, and door gaskets. Stock a small inventory of these critical spares to shorten downtime. Even technicians appreciate the confidence of knowing they’re installing parts designed specifically for your Henny Penny fryer model.

Preventive Henny Penny Fryer Maintenance Tips

Proactive care extends the life of your equipment and reduces emergency repairs:

-

Regular cleaning schedules: Remove carbon deposits, scrub frypots, and sanitize filter housings after each shift.

-

Proper oil management: Drain, filter, and top off oil daily. Rotate batches to maintain quality.

-

Periodic inspections: Check wiring harnesses, look for leaks around seals, and test safety interlocks monthly.

-

Scheduled professional servicing: Contract with a certified technician to perform quarterly tune-ups using genuine Henny Penny parts and comprehensive calibration.

A documented maintenance plan not only ensures peak performance but also provides traceability for insurance and warranty claims.

Commercial Fryer Heating Element Troubleshooting: How to Diagnose and Repair Common Issues

When to Seek Professional Help

While many issues can be handled in-house, certain scenarios call for expert intervention:

-

Complex electrical faults involving control board replacements or intricate wiring repairs.

-

Persistent temperature fluctuations after basic troubleshooting suggest deeper sensor or PCB malfunctions.

-

Oil filtration rebuilds require full system disassembly.

-

Warranty-covered failures, which should be addressed by an authorized service center using genuine Henny Penny replacement parts.

-

Professional technicians carry specialized tools and diagnostic software that streamline repairs. They can also advise on upgrades like advanced oil filtration systems to further enhance your fryer’s reliability.

Mastering Henny Penny fryer troubleshooting is key to minimizing downtime, controlling costs, and consistently serving top-quality fried foods. By understanding core fryer components, following systematic diagnostic steps, and stocking genuine Henny Penny parts, you’ll ensure your equipment operates safely and efficiently. Couple these practices with proactive cleaning schedules and professional servicing, and your Henny Penny fryers will deliver smooth operation shift after shift. PartsFe UK offers a range of commercial fryer spare parts, including fryer baskets, deep fryer filters, fryer thermocouples, and pot caster wheels. Get the required ones for your commercial kitchen needs

FAQs

How often should the oil be filtered in a Henny Penny fryer?

For best results, oil in a Henny Penny fryer should be filtered daily or after every 6–8 hours of heavy use. Frequent filtration helps maintain oil quality, improves food taste, and extends the life of fryer components.

Can I upgrade my Henny Penny fryer with newer technology parts?

Yes, many Henny Penny replacement parts and accessories are designed to be compatible with older models, allowing operators to upgrade features like controls, filtration systems, and sensors without replacing the entire fryer.