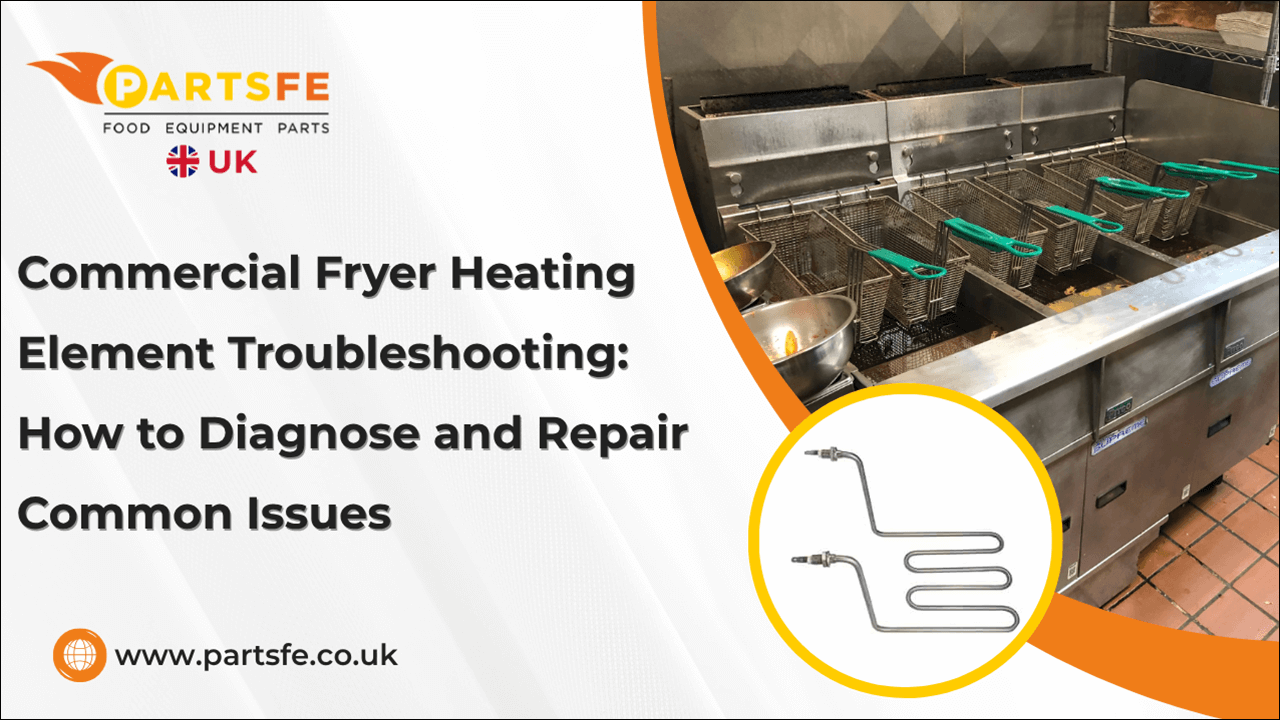

Commercial Fryer Heating Element Troubleshooting: How to Diagnose and Repair Common Issues

In any bustling commercial kitchen, the deep fryer stands as a workhorse, churning out baskets of crispy fries, chicken, and other delights. At the core of its operation is the deep fryer heating element, a crucial component responsible for rapidly bringing oil to the optimal cooking temperature and maintaining heat during service. Commercial deep fryer parts occasionally fail, among which the heating element is most prone to problems due to its intense workload and constant exposure to hot oil. Recognizing issues early can minimize downtime, reduce repair costs, and extend the life of your investment. This guide explores the importance of the heating element, symptoms of trouble, common issues, cleaning and replacement procedures, and preventive maintenance to keep your fryer running smoothly.

Understanding the Role of a Deep Fryer Heating Element

The deep fryer heating element consists of electrically heated coils or rods, usually made of robust metals capable of withstanding high temperatures and direct oil contact. When electricity flows through the element, it heats up, transferring thermal energy to the oil to reach and maintain precise cooking temperatures.

A properly working deep fryer heating element is essential for both performance and safety. If the element produces erratic temperatures or fails to operate efficiently, food quality suffers, and safety risks increase—oil that is too cool results in soggy, undercooked foods, while overheating oil can become a fire hazard.

Signs Your Deep Fryer Heating Element Is Not Working

Being able to spot the symptoms of a deep fryer heating element not working is critical for timely intervention.

-

Inconsistent oil temperature: If your fryer struggles to maintain a steady oil temperature or the recovery time after adding food seems excessively long, it could indicate that the deep fryer heating element is losing its efficiency. Fluctuating oil temperature leads to uneven cooking and impacts food quality.

-

No heat production: If the deep fryer heating element fails to warm the oil despite the appliance being powered on and the thermostat set correctly, you may need a deep fryer heating element replacement.

-

Frequent tripping or power issues: If your breaker trips whenever the fryer is turned on, it could be due to a shorted or burnt-out deep fryer heating element. Electrical faults not only halt cooking but may also pose a risk of fire or injury.

-

Erratic operation or shutdowns: Sometimes, the fryer might switch on and off at random intervals or shut down abruptly. Such erratic behavior often points to internal faults within the heating element itself or its connections.

Common Issues and Troubleshooting Tips

Understanding what can go wrong with your deep fryer heating element helps in quick diagnosis and effective solutions.

|

Issue |

Symptoms |

Troubleshooting Tip |

|

Burnt-out heating coils |

|

|

|

Wiring or connection problems |

|

|

|

Faulty thermostats or controls |

|

|

|

Control board malfunction |

|

|

|

Combination failures |

|

|

Commercial Deep Fryer Filters 101: When and How to Replace Them

How to Clean a Deep Fryer Heating Element

Proper cleaning is vital for maintaining efficiency and extending the lifespan of your deep fryer heating element. A buildup of carbonized oil or crumbs can insulate the element, causing inefficient heating and potential safety hazards.

-

Turn off and unplug: Always unplug the fryer and allow the oil and heating element to cool completely before starting any cleaning process.

-

Remove the element: Consult the manufacturer's manual for guidance. Most commercial models will allow you to lift or detach the deep fryer heating element for easier access.

-

Prepare cleaning agents and tools: Use a non-abrasive sponge, soft brush, and mild degreaser designed for use on commercial deep fryer parts. Avoid anything that may scratch or damage the element's surface.

-

Soak and wipe: If removable, soak the deep fryer heating element in warm, soapy water for several minutes to loosen stubborn grease. Gently scrub off debris and wipe clean.

-

Rinse thoroughly: Ensure no cleaning residue is left on the element, as this can cause harmful fumes or flavor contamination when reheated.

-

Dry fully before use: Let the element air-dry or pat dry with a lint-free cloth before reinstalling.

How to Perform a Deep Fryer Heating Element Replacement

A failed or inefficient heating element doesn’t always mean it’s the end for your fryer, often, an effective deep fryer heating element replacement restores optimal performance at a fraction of the cost of a new unit.

-

Shut off power: Ensure the fryer is completely unplugged or disconnected from any power supply.

-

Remove the oil: Drain and cool the oil to avoid burns or spills during handling.

-

Access the heating element: Refer to your equipment’s manual to safely open or access the compartment holding the heating element. Most commercial fryers have an access panel or removable section.

-

Disconnect the element: Carefully disconnect all wiring and mounting brackets. Note the configuration or take a photo for reference during reassembly.

-

Install new heating element: Position the new deep fryer heating element (only use compatible deep fryer replacement parts recommended for your model), reconnect wiring, and secure with existing brackets.

-

Double-check connections: Before restoring power, review all connections for tightness and correctness. Improper installation may result in immediate failure or hazards.

-

Test the fryer: After reassembly, refill with oil, power up, and check for proper operation. Monitor the first heating cycle closely to ensure the fryer temp is accurate and stable.

Preventive Maintenance Tips

Routine maintenance is crucial for prolonging the lifespan of your deep fryer heating element and other vital commercial deep fryer parts.

-

Routine inspections: Inspect your fryer before every shift for physical damage, abnormal sounds, or signs of electrical issues. Early detection can prevent larger failures and minimize downtime.

-

Proper cleaning frequency: As outlined, following a scheduled cleaning protocol daily and weekly prevents buildup and unnecessary strain on the deep fryer heating element.

-

Using high-quality commercial deep fryer parts: Investing in premium-grade deep fryer replacement parts ensures better performance and less frequent repairs. Avoid off-brand parts that may not be designed for the rigors of commercial use.

-

Avoiding common user errors: Do not overfill the oil, as this can stress the deep fryer heating element and cause electrical shorts. Never run the fryer without oil, dry firing burns out the element rapidly. Avoid setting the thermostat higher than needed, as excessive heat shortens the element’s lifespan.

How to Pick the Perfect Deep Fryer Machine for a Commercial Kitchen

Commercial fryers are indispensable in food service, and the deep fryer heating element is key to their performance and safety. Recognize the signs of trouble, address issues quickly, and choose the right deep fryer replacement parts when repairs are needed. Practicing regular cleaning using proper methods for how to clean a deep fryer heating element and following a routine inspection schedule for all commercial deep fryer parts keeps your kitchen efficient and reduces costly downtime. Take care of your equipment, and it will serve your business reliably for years to come. PartsFe UK offers a range of commercial fryer spare parts, including fryer baskets, deep fryer filters, fryer thermocouples, and pot caster wheels. Get the required ones for your commercial kitchen needs

FAQs

Can a deep fryer work with a damaged heating element temporarily?

Operating a fryer with a damaged heating element is not recommended. It can lead to uneven cooking, safety risks, and further damage to other commercial deep fryer parts.

How often should a deep fryer heating element be replaced?

Depending on usage, a deep fryer heating element should typically be inspected annually and replaced every 2–5 years, or sooner if performance issues are noted.