How Water Filters Transform Ice Quality in Commercial Ice Machines

The clarity, hardness, and overall flavour of ice rely heavily on one key factor: water quality. For hospitality businesses across the United Kingdom, such as pubs, restaurants, cafes, hotels, and catering firms, ice is not just a cold ingredient; it’s an integral part of the customer experience. When customers receive drinks with cloudy cubes, off-flavours, or ice that melts quickly, it creates a negative impression of the establishment. The surprising truth is that most ice quality issues stem not from the machine itself but from the water supplying it.

A high-quality commercial ice machine water filter transforms the taste, appearance, and hygiene of ice from the inside out. These filters remove chlorine, sediment, rust, scale-forming minerals, and microbial contaminants that compromise the cubes and damage machine components. With the right inline ice machine water filter, businesses can significantly cut maintenance costs, improve ice production reliability, and extend the equipment’s lifespan. This article examines various types of ice machine water filters, their operational principles, and the importance of filtered water in producing premium-quality ice.

What Ice Machine Water Filters Do & Why They Matter for Ice Quality and Food Safety

A water filter improves ice quality by:

-

Removing chlorine and chemicals that affect the drink's flavour

-

Reducing sediment that clouds ice

-

Preventing limescale, protecting evaporators

-

Reducing microbial contamination

This results in harder, clearer, safer ice and reduced machine breakdowns.

For equipment longevity, filtration is equally important. Limescale caused by hard water can accumulate on evaporator plates, causing slow harvest cycles and reduced production capacity. In extreme cases, scale buildup forces machines to shut down for safety. Filtering the water reduces these risks and keeps the machine running reliably.

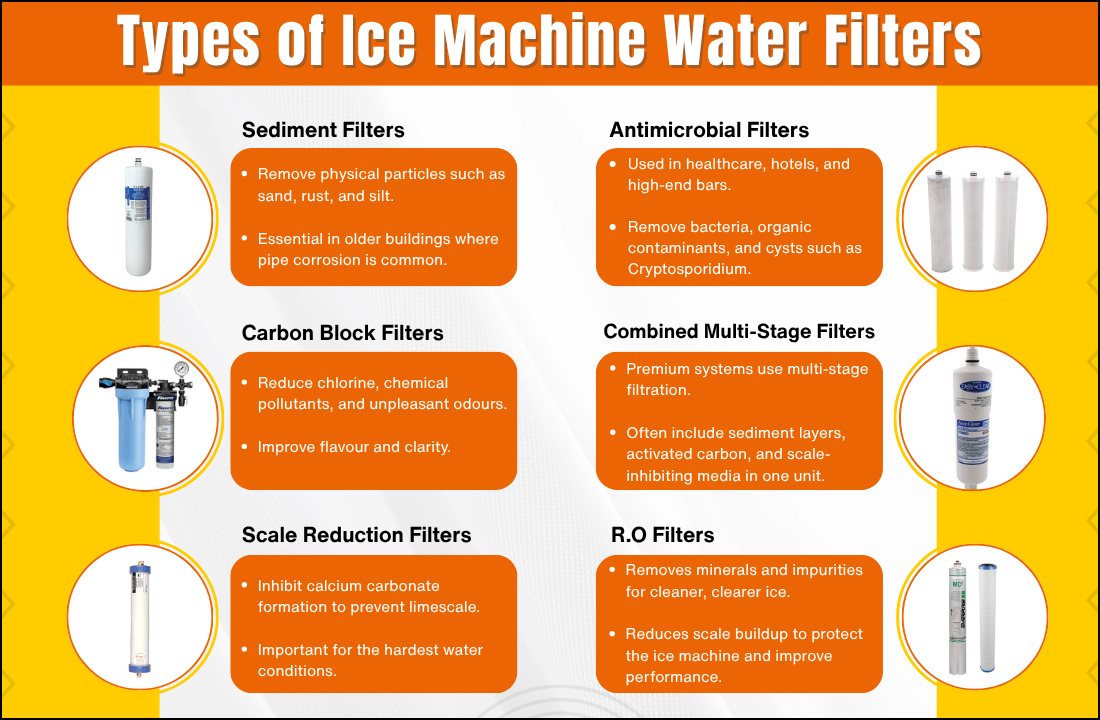

Different Types of Ice Machine Water Filters

Every type of filter addresses a different water quality issue, some focus on taste, others on scale control. Here are the different types of ice machine water filters widely used in the UK:

Brands like Hoshizaki ice machine water filter, Manitowoc ice machine water filter, and Scotsman ice machine water filter rely on these advanced cartridges. A high-quality ice machine water filter cartridge often contains sediment layers, activated carbon, and scale-inhibiting media in one unit.

Benefits of Using a High-Quality Water Filter in Commercial Kitchens

Using the right filter improves quality, safety, efficiency, and machine lifespan.

These benefits have both operational and financial impacts.

-

Clearer ice with better appearance: Filtered water freezes more evenly, producing transparent ice. Clear ice signals cleanliness and professionalism to customers.

-

Improved beverage flavour: Chlorine interacts heavily with alcoholic beverages. A good filter removes chlorine, enhancing the natural flavour of drinks.

-

Reduced limescale build-up: Without filtration, scale can clog valves, cover evaporators, and damage pumps. Scale reduction filters prevent thousands of pounds in repair costs.

-

Longer machine life: Clean water protects sensors, floats, and water pumps. Machines last significantly longer when scale and sediment are controlled.

-

Lower energy consumption: Scale forces the machine to work harder. Filtered water keeps evaporators clean, reducing energy waste.

-

Better hygiene for food safety: Bacteria and cyst reduction ensure ice meets UK hygiene standards. This is crucial in catering environments that serve vulnerable individuals.

-

Consistent ice production output: Clean water ensures faster harvest cycles and stable production volumes. This prevents shortages during peak service periods.

By switching to the best water filter for commercial ice machine installations, operators secure both machine performance and customer satisfaction.

How to Choose the Right Water Filter for Your Ice Machine

Choosing the right filter is essential to maintain clarity, taste, and hygiene.

Several factors should guide the decision, including brand, water hardness, usage, and capacity.

1. Identify water hardness levels

-

The UK is dominated by hard water areas. Cities like Birmingham, London, and Oxford require strong scale-reducing filters.

2. Choose a brand-compatible filter

Machine-specific filters ensure correct flow rates:

-

Manitowoc ice machine water filter

-

Scotsman ice machine water filter

This prevents pressure imbalance and ensures optimal performance.

3. Consider multi-stage filtration systems

-

These offer taste improvement, sediment removal, and scale control in one unit. Multi-stage systems give the best balance of performance and cost-efficiency.

4. Select the proper capacity for usage

-

High-volume establishments need larger filter capacity. Small cafés may opt for lower-capacity inline filters.

5. Choose genuine cartridges only

-

A genuine ice machine water filter cartridge prevents leaks and premature clogs. This also protects the manufacturer’s warranty.

Find out How to Clean an Ice Machine Water Filter: The Ultimate Guide

Leading Ice Machine Water Filter Brands in the UK

UK businesses trust several leading brands for high-performance filtration. These brands offer reliability, long life, and strong protection against UK water issues.

|

Brand |

Key Highlights |

|

Everpure |

|

|

Hoshizaki |

|

|

Manitowoc |

|

|

Scotsman |

|

|

AquaPure / 3M |

|

Simple Maintenance Tips to Keep Your Water Filter Working Efficiently

Simple maintenance extends machine life and ensures clean, clear ice.

Following these tips prevents downtime and poor-quality ice production.

-

Replace filters on schedule: Most filters require replacement every six months. Heavy-use sites should consider shorter intervals.

-

Flush the filter after installation: This clears carbon dust and improves taste quickly. Flushing is essential for achieving the full flow rate.

-

Regularly inspect for limescale: Look at the water inlet, bin sensor, and evaporator. Hard water regions may require monthly inspection. Learn how to clean ice machine water filter housings. Regular cleaning prevents odours and bacterial accumulation.

-

Keep spare cartridges available: This avoids emergency downtime when the filter expires.

-

Clean the machine’s water path: Even with a filter, routine internal cleaning is crucial. Using bold colour-free chemical cleaners keeps water pathways hygienic.

Explore How to Diagnose and Replace a Commercial Ice Machine Water Pump

Conclusion: Why Clean, Filtered Water Is Essential for Better Ice and Longer Machine Life

Filtration enhances clarity, hardness, taste, and hygiene. Scale, chlorine, sediment, and bacteria are constant threats to ice quality and machine performance. Choosing the best water filter for commercial ice machine systems is essential for maintaining standards, reducing repair costs, and ensuring customer satisfaction. With the correct filter and regular maintenance, businesses benefit from crystal-clear ice, better beverage presentation, and significantly longer equipment lifespan. PartsFe UK offers a wide range of commercial ice machine replacement parts, including ice machine bins, ice machine water filters, ice maker water valves, ice probes & sensors, lid hinges, air filters, and compressor relays from top manufacturers at affordable prices.

FAQs

Why does ice taste bad after changing filters?

Ice can taste bad after changing filters because trapped air, loose carbon particles, or an improperly flushed ice machine water filter can affect the flavour. Running several batches clears the taste.

What are the FDA rules for ice machines?

The FDA rules for ice machines require using sanitary materials, regular cleaning, proper water filtration, and maintaining safe, contaminant-free ice handling conditions in commercial settings.

How often to change water filter on ice machine?

The recommended schedule to change the water filter on an ice machine is every 6 months, but high-volume or hard-water locations may need more frequent replacement.