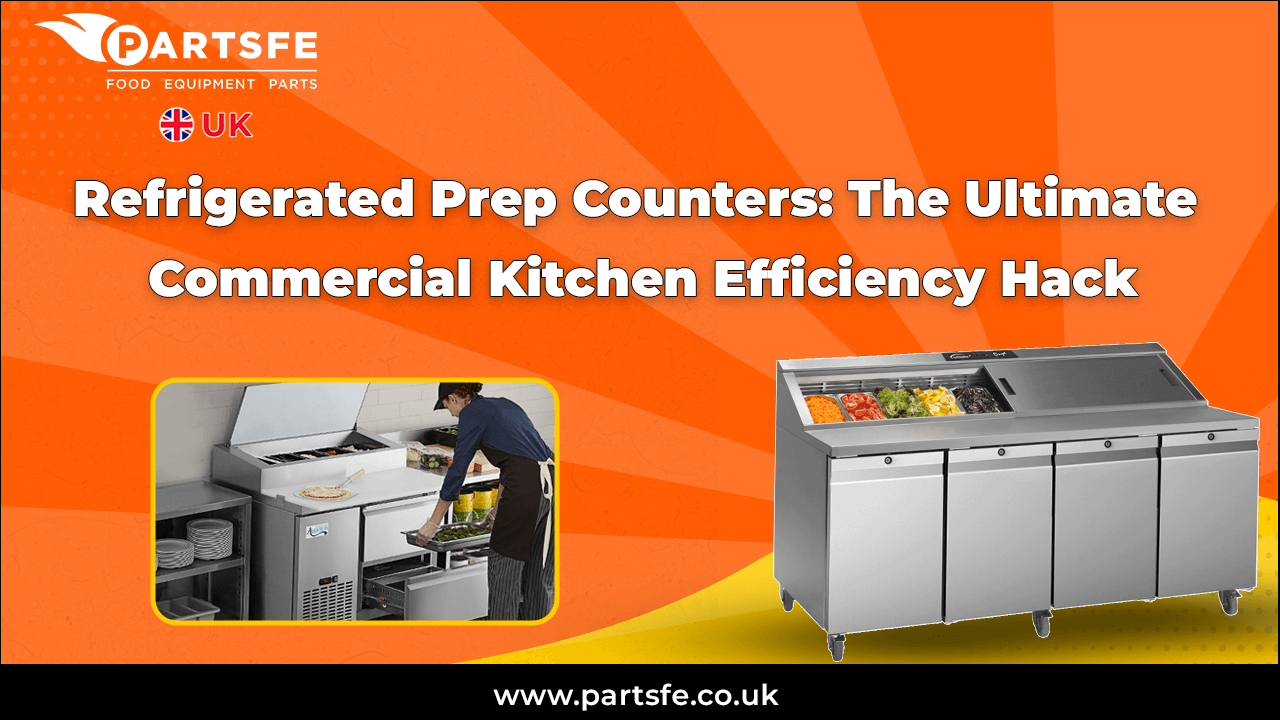

Refrigerated Prep Counters: The Ultimate Commercial Kitchen Efficiency Hack

In the fast-paced world of commercial kitchens, efficiency is the name of the game. Chefs and kitchen staff constantly juggle multiple tasks, striving to deliver high-quality meals while battling the clock. From prepping ingredients to assembling dishes, the workflow in a bustling kitchen can often feel like a chaotic dance. One of the biggest challenges is minimizing downtime and unnecessary movement, ensuring that ingredients are readily available and food safety standards are consistently met. This is where the unsung hero of modern foodservice steps in: the refrigerated prep counter. These innovative workstations combine the convenience of a preparation surface with the crucial element of integrated refrigeration, creating a seamless and efficient workflow. In this article, we'll delve into the world of refrigerated prep counters, exploring how they can revolutionize your kitchen's operations, improve food safety, and ultimately boost your bottom line.

What Are Refrigerated Prep Counters?

Refrigerated prep counters are specialized pieces of equipment designed to streamline food preparation in commercial kitchens. They are a combination of a durable work surface and a refrigerated storage base. This clever design allows chefs and kitchen staff to prep ingredients directly above a chilled storage area, keeping everything within easy reach.

-

A typical refrigerated prep counter consists of a stainless-steel worktop, which provides a hygienic and easy-to-clean surface for food preparation.

-

Beneath the worktop lies a refrigerated cabinet, equipped with drawers, doors, or a combination of both.

-

This refrigerated base is designed to maintain consistent temperatures, ensuring that ingredients remain fresh and safe for use.

Key features:

The main advantage of refrigerated prep counters is the integration of cold storage directly beneath the prep surface. This reduces the need for kitchen staff to constantly walk back and forth to walk-in refrigerators, saving valuable time and energy. Ingredients are stored at optimal temperatures, which reduces the risk of spoilage and maintains their quality.

Types of prep counters

Refrigerated prep counters come in various configurations to suit different culinary needs.

-

Pizza prep counters: Designed with a wide, flat work surface and refrigerated storage for pizza toppings, dough, and sauces.

-

Salad prep counters: Feature multiple pan holders for storing a variety of salad ingredients, along with a chilled work surface to keep greens crisp.

-

Sandwich stations: Offer a combination of pan holders, drawers, and cutting boards, ideal for assembling sandwiches and wraps with fresh ingredients.

How Refrigerated Prep Counters Improve Kitchen Workflow

The primary benefit of refrigerated prep counters is their ability to enhance kitchen workflow, leading to increased efficiency and productivity.

-

Reduces food handling time: By keeping ingredients within arm's reach, refrigerated prep counters significantly reduce food handling time. Chefs can quickly grab the necessary components for a dish without having to interrupt their workflow.

-

Keeps ingredients within reach: The ergonomic design of refrigerated prep counters ensures that all essential ingredients are readily accessible. This eliminates unnecessary stretching or reaching, minimizing the risk of accidents and maximizing comfort for kitchen staff.

-

Minimizes trips to walk-in refrigerators: One of the biggest time-wasters in a commercial kitchen is the constant need to retrieve ingredients from walk-in refrigerators. Refrigerated prep counters eliminate this issue by providing on-the-spot cold storage, saving valuable minutes and reducing the overall workload.

-

Enhances multitasking during rush hours: During peak service times, efficiency is paramount. Refrigerated prep counters enable kitchen staff to multitask effectively, preparing multiple dishes simultaneously without having to leave their workstation.

Temperature Control and Food Safety

Maintaining proper temperature control is crucial for food safety, and refrigerated prep counters excel in this area.

-

Integrated refrigeration systems: These counters are equipped with integrated refrigeration systems that are designed to maintain consistent temperatures throughout the storage area. This ensures that ingredients remain within the safe temperature range, minimizing the risk of bacterial growth.

-

Helps maintain HACCP compliance: Hazard Analysis and Critical Control Points (HACCP) is a systematic approach to food safety that identifies and controls potential hazards. Refrigerated prep counters play a vital role in HACCP compliance by providing a reliable means of maintaining proper temperature control.

-

Reduces risk of spoilage and cross-contamination: By keeping ingredients chilled and contained, refrigerated prep counters reduce the risk of spoilage and cross-contamination. This helps to ensure that the food served to customers is fresh, safe, and of the highest quality.

Versatility Across Foodservice Operations

Refrigerated prep counters are versatile pieces of equipment that can be used in a variety of foodservice operations.

-

Restaurants: Ideal for preparing appetizers, salads, sandwiches, and desserts.

-

Delis: Perfect for assembling sandwiches, wraps, and deli platters.

-

Catering kitchens: Essential for preparing large quantities of food for events and parties.

-

Food trucks: Provide a compact and efficient solution for preparing food on the go.

Refrigerated prep counters can be customized with a variety of features to meet the specific needs of each kitchen. Drawers, doors, and pan holders can be configured to maximize storage space and accessibility.

Space Optimization and Storage Efficiency

In many commercial kitchens, space is at a premium. Refrigerated prep counters help to optimize space and improve storage efficiency.

-

Combining storage and worktop saves space: By combining a work surface and a refrigerated storage base into a single unit, refrigerated prep counters save valuable floor space. This is especially beneficial in smaller kitchens where every square foot counts.

-

Helps declutter workstations: Refrigerated prep counters help to declutter workstations by keeping ingredients organized and within reach. This reduces the amount of clutter on countertops, making it easier for kitchen staff to work efficiently.

-

Ideal for small to mid-sized kitchens: These counters are particularly well-suited for small to mid-sized kitchens where space is limited. Their compact design and efficient storage capabilities make them a valuable asset in any kitchen.

Choosing the Right Prep Counter for Your Kitchen

Selecting the right refrigerated prep counter for your kitchen is an important decision that can have a significant impact on your operations.

-

Size: Choose a prep counter that is appropriately sized for your kitchen and the amount of food you prepare.

-

Type of cuisine: Consider the type of cuisine you serve and select a prep counter with features that are tailored to your needs.

-

Pan capacity: Ensure that the prep counter has sufficient pan capacity to hold all of the ingredients you need for your recipes.

-

Energy efficiency: Look for a prep counter with an energy-efficient design to minimize your utility costs.

How to Choose the Right Commercial Refrigerator for Restaurant Efficiency

Maintenance and Cleaning Tips

To ensure optimal performance and longevity, refrigerated prep counters require regular maintenance and cleaning.

|

Maintenance Area |

Details |

|

Stainless steel durability |

Durable and corrosion-resistant, but requires regular cleaning to avoid food buildup and stains. |

|

Easy-to-clean surfaces & trays |

Designed with smooth surfaces and removable trays for hassle-free cleaning. |

|

Regular defrosting |

Prevents ice buildup and ensures efficient cooling. |

|

Condenser cleaning |

Periodic cleaning helps maintain airflow and cooling performance. |

By integrating cold storage with a convenient prep surface, these counters minimize food handling time, optimize space, and ensure that ingredients remain fresh and safe. Whether you run a bustling restaurant, a busy deli, or a catering operation, a refrigerated prep counter can be the ultimate efficiency hack, streamlining your workflow and boosting your bottom line. Investing in a high-quality refrigerated prep counter is not just about upgrading your equipment; it's about investing in the future of your kitchen's success. PartsFe UK is the online store for commercial ice machine replacement parts for your business. We have OEM replacements from manufacturers such as Manitowoc and Hoshizaki at affordable prices.

FAQs

Can refrigerated prep counters be used in outdoor catering setups?

Yes, but they must be rated for outdoor use and protected from direct sunlight and rain. Portable refrigerated counters with secure power sources are ideal for mobile catering or outdoor events.

How do refrigerated prep counters affect energy consumption in a kitchen?

While they use additional power compared to a standard prep table, they reduce the load on walk-in refrigerators and minimize food waste, often leading to net energy and cost savings over time.